Best Welding Work Shoes

List of Best Welding Work Shoes

FAQ

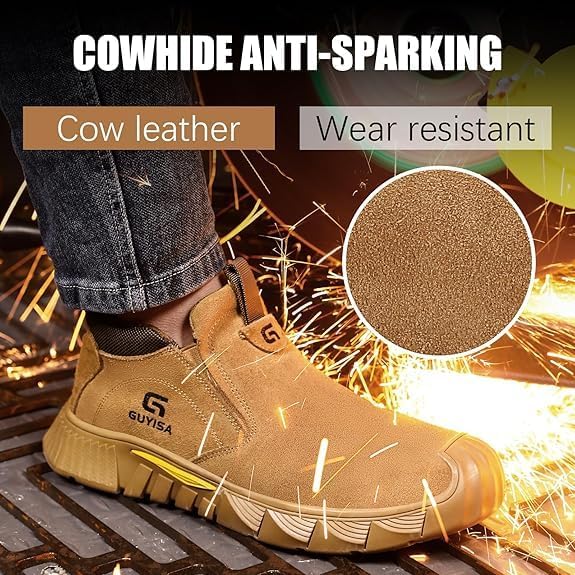

Quality welding work shoes often feature steel or composite toe caps, slip-resistant soles, and heat-resistant materials. These elements are crucial for protecting your feet from heavy equipment and sparks, making them essential for safety on the job site.

Comfort is vital, especially during long shifts that may last 8 to 12 hours. Many modern designs incorporate cushioned insoles and breathable materials to minimize fatigue and pressure points, ensuring you can focus on your work without discomfort.

Women should consider designs that offer a snug fit while still providing the necessary protection. Some brands create women's-specific models with narrower widths and tailored features that accommodate different foot shapes, ensuring both comfort and safety on the job.

To find the right size, measure your feet in the afternoon when they are slightly swollen for an accurate fit. It's also recommended to try footwear while wearing the socks you intend to use at work, as this can affect the overall fit.

Yes, many welding work shoes are designed for both indoor and outdoor environments. Look for options with water-resistant features if you will be working on grass or uneven surfaces, as this can provide added stability and comfort throughout your tasks.

Proper maintenance includes cleaning them regularly to remove dirt and debris, which can wear down materials. Additionally, applying a protective spray can help guard against sparks and other hazards typically found in welding environments.

The sole material significantly impacts traction and stability. Rubber soles, for instance, offer excellent grip on oily or uneven surfaces, which is essential for preventing slips and falls in various work environments.

Absolutely, many welding work shoe designs are versatile enough for other trades like construction or manufacturing. However, ensure they meet the specific safety standards required for those jobs, particularly concerning toe protection and slip resistance.